How construction can become sustainable

20 September 2021

The construction industry is undergoing a transformative shift to adapt more environmentally friendly practices. Lindsey Anderson investigates what construction companies can do to become greener and cleaner

While efforts are underway to make the construction industry more sustainable, data from the Global Alliance of Buildings and Construction’s Global Status Report shows just how far we still have to go.

Just two years ago, the Global ABC’s Building Climate Tracker unveiled a stark reality – emissions from the buildings and construction industry hit an all-time high. More than 38% of global carbon emissions come from building and construction operations. On top of that, construction uses about 32% of the world’s natural resources.

Increasing emission incentives and zero-emission targets coming into play in recent years have had a marked effect on the increase in greener equipment and jobsites.

Increasing emission incentives and zero-emission targets coming into play in recent years have had a marked effect on the increase in greener equipment and jobsites.

“Construction has an undeniable and vital role to play in limiting global warming,” says Nathan Swankie, UK County Director, Environment & Health, Ramboll. “There is great talent in our industry, and we must harness it to address this global challenge. We must focus on skills and innovation and be bold in our pursuit of the needed transformational change.”

Understanding carbon and climate change

At the most basic level, carbon and climate issues must be understood by everyone within an organisation – not just specialists. One way to start the conversation is through education and training.

Jacobs Engineering Group is one company doing just that. The US-based firm recently announced that it is offering its entire workforce the opportunity to take the Climate Solutions Accelerator course, a 90-minute online program that focuses on need-to-know information while outlining key solutions to respond to climate change.

The course helps to explain how everyone and every organisation can play a role to reduce emissions and informs businesses and organisations on how they can plan better and predict future trends and legislation.

“Effectively responding to the threat of climate change requires all of us to work together – businesses, governments and communities around the world,” said Jacobs Chair and CEO Steve Demetriou.

“Our shareholders are becoming increasingly focused on Environmental, Social and Governance (ESG) transparency. Our clients are talking to us every day about how to decarbonise their businesses and move towards meeting national industry targets. And our employees consistently expect Jacobs to lead by example when it comes to sustainability and climate action.”

By ensuring there is a baseline level of carbon and climate literacy across the industry, sustainability can become a part of everyday conversations, thus bolstering green practices and initiatives.

Ramboll is also using training to bring awareness to its team members and clients. The company upskills its people through understanding the climate emergency at hand, and Ramboll has also taken on technical training by discipline to ensure climate considerations are methodically embedded into all design and advisory outputs.

Nathan Swankie, UK County Director, Environment & Health, Rambol.

Nathan Swankie, UK County Director, Environment & Health, Rambol.

“The industry needs to upskill at speed and close the green skills gap; we must ensure a baseline level of carbon and climate literacy across the industry as well as enabling advanced pioneers,” says Swankie.

“Green skills cannot sit only within specialised teams, it must extend across an organisation. But we must also be bold in empowering and mobilising sustainability pioneers, giving funding, creating new emerging roles and supporting the challenge to the status quo.”

Improving sustainability in construction

Victoria Burrows, Director, Advancing Net Zero, World Green Building Council, agrees. “Improving sustainability in construction starts in the design phase long before the first shovel hits the ground,” Burrows says. “However, construction companies play a significant role in translating those designs into reality.”

Sustainable construction is evolving at a fast, almost break-neck pace. It requires companies to ensure they stay up to date with the latest sustainable practices, materials and technologies. By finding ways to reduce waste, avoiding damage and curbing rework, projects become leaner and more efficient.

Integrated project delivery and lean construction practices encourage efficient processes and outcomes, and help meet sustainability goals of owners, designers and contractors. Construction companies can improve sustainability by developing and implementing construction policies and documentation practices that explicitly state why, how, when, what and by whom things will be done.

Burrows says other considerations that contribute to improved sustainability include: site accommodation specification, worker welfare, community engagement, biodiversity considerations, sustainable transportation during construction, training and education about sustainability issues, commissioning and testing, and compliance with certification schemes.

By planning sustainable practices across entire processes – from the construction phase of the project, use phase and end of life phase – ‘green’ methods become normalized and seamless.

“That is why integrated design and involvement of construction companies in the early stages of the project, including their advice on buildability, material selection and construction methods and techniques, is extremely valuable,” says Burrows.

Sustainable practices in construction

For construction to reduce its carbons and emissions then all sectors have to work together, but there is no doubt that the OEMs are a vital cog in the wheel. Finnish company Metso Outotec provides technology and services for mining, aggregates, recycling and metal refining industries. The manufacturer says it is relentlessly searching for ways to increase efficiency and reduce waste.

“The crushing and screening segment is constantly looking to be more environmentally efficient and to increase our sustainability in terms of looking to reuse materials wherever possible which can be seen by the ever-increasing recycling segment,” says Adrian Wood, VP, distribution, EMEA at Metso Outotec.

“I believe it is our responsibility as a manufacturer not only to make equipment greener by being more efficient and using energy wiser, but also looking at different processes to limit the use of natural resources.”

Metso Outotec’s main goal is to reduce waste, find new ways to use waste that has accumulated over many years and reuse what is available today. The company is also looking at limiting transport – making direct point to point deliveries rather than transporting to storage centres.

Metso has reducing its waste is a key priority.

Metso has reducing its waste is a key priority.

Ramboll’s Swankie says the industry’s biggest sustainability ‘trend’ is designing new, efficient machines that increase the percentage of premium products while reducing the amount of waste. “We must remember, though, different markets have vastly different premium products, so we need the flexibility to adjust accordingly,” he says.

Swankie adds that they are now seeing sustainable approaches moving from being an ‘add-on’ to being the starting and central point of a project. “With mounting public consciousness, a fast-evolving regulatory landscape, and heightened expectations from financial institutions, we have certainly seen a surge in requests from clients for more substantial sustainability support.”

Clients increasingly want to stand out from the crowd by distinguishing themselves through their sustainability approaches. “As more businesses plan for a net zero, climate resilient future, it is encouraging to see the level of understanding improving and the demand for sound reasoning and clear evidence of sustainable approaches increasing,” he notes.

Construction’s environmental impact

When thinking about building – and projected structural lifespans – the construction phase is relatively short. However, the construction sector can have an enormous influence on how buildings are built, where materials are sourced from, and how to reduce emissions and environmental impacts of the construction phase.

Construction also plays a critical role in maximising the quality and positive impact of the finished structure, ensuring the completed building will go on to operate as efficiently as possible.

Buildings are built one at a time, but they join an enormous ecosystem of potential to generate and share energy with nearby buildings, respond to the needs of users and the external environment, and create enhanced quality of life for all who interact with them.

Burrows from the World Green Building Council points out the potential for buildings to operate as power generation stations, and integrate with other systems like transport, optimises their potential to serve both the needs of society today and future generations.

“Buildings must be flexible and adaptable to future-proof conditions, needs and priorities,” she explains. “It must be an easier choice to build a building responsibly — or to renovate an existing building and extend its useful life — than to continue unsustainable levels of resource consumption and emissions.

“The planet’s limited resources forces us to reconsider our approach to development, to ensure that by meeting the needs of today we are not causing irreversible damage for the future.”

Photo credit: Reuters. Swedish green steel venture HYBRIT announced it made the world’s first customer delivery of steel produced without using coal.

Photo credit: Reuters. Swedish green steel venture HYBRIT announced it made the world’s first customer delivery of steel produced without using coal.

One way to address this is to look at buildings as material banks – with materials being hosted or leased by a building for future re-use. This idea also helps to create a cycle for future construction.

Burrows explains that planning ahead for disassembly seeks to achieve reversible building design with cradle-to-cradle thinking that extends the useful life of building materials into future projects, instead of demolition where material recovery is challenging.

“The long-term concepts of sustainability will grow in the future and expand to not only reduce or eliminate the environmental, social and economical impacts of projects, but rather to catalyse a positive impact,” she says.

Sustainability strategies

Actions taken to improve sustainability are effective when they are guided by sustainability strategies and policies, with monitoring and evaluation actions in place, then disclosing progress by producing sustainability reports. Some organisations use techniques that involve internal organisational carbon taxes on materials and resources, such as waste, water or diesel, to limit consumption.

A case study example of a construction company who integrated sustainability into their business is Multiplex, who created One Decade to Act vision. Multiplex started the program with cultural and behavioral change, performed data collection for their business performance and established baselines, analysing the data to set science-based targets and committed to achieve them.

Multiplex’s actions are not limited to on-site practices but extend to a detailed plan and strategy that cover all stages of building, from design, planning, procurement, construction and handover.

This extensive plan requires the engagement of all stakeholders including clients, entire supply chain and consultants. And there’s also a large target to hit: zero onsite emissions by 2025, 50% reduction in embodied carbon intensity by 2030, net zero carbon building operations by 2030, zero transport emissions by 2030 and zero avoidable waste by 2030.

This type of dedication to green practices and a sustainable future is what construction companies should strive for, says Ramboll’s Swankie.

“Our industry needs to innovate and innovate fast – but it is an exciting opportunity fueled by real purpose,” he says. “It will take courage and commitment from businesses to innovate, and by clients to try and accept innovative approaches in a safe way. It will take diversity of thought, a willingness to change and think differently, and commitment to prioritise sustainability in business strategy, operations and procurement.”

Construction companies can support these efforts by educating clients, peers, suppliers and wider stakeholders on the decisions being made, the reasoning behind them, and the negative impact of alternative choices. It is no longer a question of if it will happen; it’s a question of are you ready.

“Awareness of these issues is helping to mitigate the problem, but action will help overcome them,” Burrows concludes. “Whilst in the past years we have seen positive change in the way buildings are designed, constructed and operated; resulting in spectacular examples of high performance new and renovated buildings providing enhanced quality of life, there is still a huge amount to be done.”

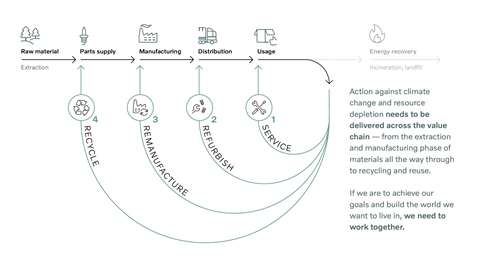

Volvo CE’s path to sustainabilityMajor OEM sets out how construction can become more sustainable The journey toward a more sustainable construction industry is well underway with a clear roadmap ahead to deliver carbon neutral equipment fit for the future. Battery electric and fuel cell electric products form a major part of this ambition. But if we want to reduce our environmental impact and build the world we want to live in, there are many more factors to consider. Volvo Construction Equipment (Volvo CE) has a commitment to reach net zero value chain greenhouse gas emissions by 2040. Developing battery electric vehicles and fuel cell electric technology will go a long way to deliver on that ambition, but for a construction company today, there is much more to do to drive industry change The company has set out four key strategies: Get everyone on the carbon reduction pathway, Take action across the supply chain with a circular approach, Leverage the power of partnerships and Use data to deliver on sustainability goals. “Climate change is real and one of the greatest challenges of our time. As a world leading manufacturer, we not only have a responsibility to reduce our carbon footprint, we also have the clear vision, determination and talents to drive this transformation that is so urgently needed now. The choices we make today will form the world tomorrow – and we choose to act,” concludes Melker Jernberg, President of Volvo CE. |

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM