BIM: Taking formwork to the next level

11 November 2022

Rapid urbanisation, growth of city-centric commerce and corresponding infrastructure development have heightened construction activity across the globe. Consequent challenges of construction project optimisation and need for shorter time-to-market, along with digitisation, have brought BIM to the centre of the stage. BIM-centric approaches have become critical in improving productivity, accuracy and resource optimisation in formwork.

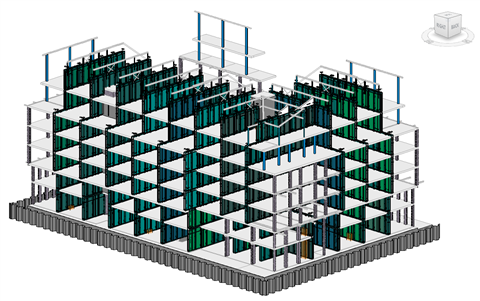

A structural BIM model with formwork. Image: TrueCADD

A structural BIM model with formwork. Image: TrueCADD

Formwork is often not given its due importance within the construction industry as it is deployed towards the end of detailing operations. Traditional workflows inhibit feedbacks from formwork contractors or suppliers during the designing, modelling, and approval process, though it should be included in the design table early in the planning stage.

Let us understand how modular formwork enrichment with the use of BIM (Building Information Modelling) helps in modulating the required formwork pieces, optimising the use of available formwork and reusing them and creating custom modules as required. It’s time to change the perception that temporary work merits lower importance. Formwork is just as important as other project works in construction.

What is formwork and why is it important for building construction?

Concrete is one of the most extensively used building materials. To construct building components, concrete needs to be poured into a specialised design mould, called shuttering or formwork. Formwork uses permanent or temporary moulds to hold the concrete in a specific shape until it becomes solid and gets the required strength for support.

The adoption of formwork plays a crucial role in the construction of concrete buildings or structures. A good formwork design needs to gain optimum strength for load-bearing during casting and concrete hardening. Also the formwork moulds can not only be customised but reused for future construction projects, making it a cost-effective and viable option.

How adopting BIM improves coordination and drives higher visibility for formwork

3D modelling of formwork of a concrete structure has significant advantages for the overall project. Higher visibility can be achieved with complete coordination in BIM, which enables better clash identification and resolution, and other design ambiguities. Project stakeholders can save both time and money with improved planning and scheduling, better transparency, collaboration, and efficiency.

BIM tools like Revit and Navisworks reinforce visualisation with accurate schedules and costs. Quantities calculated from BIM-based tools are faster than 2D drawings. Information within the model can generate quick estimates with no manual intervention. Parametric 3D models give you the flexibility to make modifications to calculate precise quantities.

TrueCADD’s Bhushan Avsatthi

TrueCADD’s Bhushan Avsatthi

Top 4 BIM-centric applications for formwork construction

1. BIM automates quantity take-offs & estimation for formwork

Temporary work, field structures with accurate quantities, capacities, and logistical planning needs to be carried out to move formwork construction in the right direction. Scaffolding to support the formwork and the load before pouring needs to be calculated.

The 3D Revit models have automatic updates which means that any changes or modifications in material quantity or cost is automatically updated. Also, the three-dimensional visualisation helps gain better clarity of the exact location, sequence or pour type for formwork components.

2. BIM streamlines the formwork construction process

BIM eliminates the risk of manual errors as all the modifications are coordinated and documents and drawings are extracted from the coordinated 3D Revit model for placing of formwork components.

Building elements can be created in 3D to build transparent workflows. A higher level of detail helps create accurate formwork plans. The detailed and accurate BIM model speeds up the formwork construction process with minimal manual interference.

3. Clash-detection with 3D BIM models solves formwork issues

In a three-dimensional BIM model, clashes are easier to detect and issues can be resolved quickly, saving money and time. When clashes are identified and resolved at the pre-construction stage, potential formwork constructability problems are easily resolved.

Formwork components can be placed in the right location and at accurate angles without any clashes.

4. BIM offers easy access to formwork models for all stakeholders

Formwork requires planning and BIM-based 3D models provide logistics professionals with easy access to information on the placing of formwork on various site locations. BIM models on a cloud platform like BIM 360, can be accessed by various stakeholders at any location and on any device.

Any changes or updates made are automatically updated. This helps keep formwork contractors on the same page and brings greater project.

Wrapping it up… BIM to enhance formwork construction

Formwork can’t be replaced with any other process or technology. It not only helps lower construction costs but ensures that project timelines are met.

With construction materials being long lasting and robust, contractors can build practical and safer construction projects by adopting and implementing formwork in integration with BIM.

|

About Author Bhushan Avsatthi is an architect with over 22 years in the field. He oversees the BIM division of TrueCADD, managing multiple teams of architects, structural and MEP engineers, LEED consultants and energy modelling experts. Bhushan has spoken at various international BIM conferences and is deeply involved in green initiatives. His thoughts on global best practices in building design have been published in multiple architectural and engineering journals. |

CAPTION (Above taking formwork to the next level)

Structural model with formwork

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM